Insights

Embodied Carbon – What’s Inside Is What Counts

Sustainable architecture is good, energy-efficient and smart homes are great – but in order to optimize the carbon footprint of a building, the construction industry needs to go one step further and also address embodied carbon.

We have to face up to an inconvenient reality: almost 40 percent of global CO2 emissions come from buildings. There have been a lot of reports about this, and those responsible in the construction and real estate industries have been aware of it for a long time. However, many are taking up the challenge of reducing CO2, ensuring sustainable transformation and making a decisive contribution to global climate protection through sustainable construction of low-emission buildings.

What is often overlooked, however, is that building managers and contractors aren’t alone in tackling the issue of minimizing CO2. The battle to reduce emissions must begin earlier. Only two thirds of the CO2 emitted by buildings is operational carbon, which is produced by heating and cooling. The last third is embodied carbon.

What Is Embodied Carbon?

In short, embodied carbon is the carbon footprint of materials. It refers to the greenhouse gas emissions of materials, and includes all emissions generated during the production, transport, installation, maintenance and disposal of building materials.

How and Where is Embodied Carbon Created?

“From cradle to gate” is the principle, and it focuses on the supply chain. It all begins in the “cradle”, i.e. the place where raw materials are obtained.

For example, heavy machinery generates CO2 when quarrying stone or sand, which later becomes concrete or mineral wool. Equipment used to cut down trees for wood production also does the same. Energy must be used to burn, press, cut or dry the materials. Their carbon footprint must be included in the supply chain carbon footprint, as must that of the factory where, e.g. basalt is turned into insulation.

Likewise, CO2 emissions from the transporting of processed materials to the construction site, where they become part of the building – along with all their embodied carbon – must be considered.

Best Practices

With Tomorrow in Mind: Sustainable Architecture and Climate-Friendly Buildings

Learn more about the lifecycle approach in our new white paper

Embodied Carbon versus Embodied Energy

It could be tempting to say that all building materials whose production is energy-intensive automatically have a worse carbon footprint and a higher proportion of embodied carbon. However, this is not true: it strongly depends on the proportion of renewable energy used between the cradle and the gate. That’s why it’s important to keep an eye on embodied energy, i.e. the emissions generated during the operation of a building, as well as on the embodied carbon.

Here’s an interesting, albeit extreme example: a recent study compared the life cycle assessment of two kinds of bricks, one traditionally manufactured and sun-dried, and the other conventional, industrially manufactured and fire-clayed. The expected result: the former provides a reduction of up to 5907 kg Co2e and 5305 MJ of embodied energy for every 1,000 bricks.

How Do You Measure the Carbon Footprint of Building Materials?

Measuring embodied carbon is a slightly complicated process. But it is important, as it accounts for 11% of global CO2 emissions. This is where there is great potential for reducing emissions and advancing sustainable transformation. Looking only at the CO2 emissions from the operation of a building is clearly not sufficient. Sooner rather than later, anyone committed to sustainable construction and sustainable buildings must address the issue of embodied carbon and ways to reduce it.

This is intended to help the construction industry, banks and also politicians to formulate ambitious yet realistic goals in terms of reducing embodied carbon and measuring success. True to the motto: “What gets measured gets done.”

So far, the life cycle assessment (LCA) method and tools such as the building information model (BIM) have helped when it comes to calculating the carbon footprint of certain materials. The useful life of a building is divided into different stages, and then the respective carbon footprint of each stage is determined. These range from the materials used and construction stage to the operating phase through to demolition and the recycling of materials.

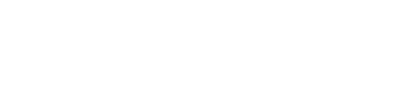

Four Ways to Reduce Embodied Carbon

There are different approaches to improving the intrinsic carbon footprint of buildings.

Number one is definitely recycling, e.g. the further use and reuse of existing materials, or a change of use. A current example of this is Berlin’s decommissioned Tegel Airport that is being converted into a digital hub. Repurposing rather than building from scratch is how to effectively achieve emissions savings. It goes without saying that there’s less embodied carbon added to the overall result where fewer new materials are used.

Number two: if the entire building cannot be reused, it may be that certain components and materials can. The keyword here is circular economy, which forms an essential part of sustainable construction. In the same way, existing materials already carry their immanent carbon footprint, while new greenhouse gases are added for new materials.

Number three: when buying new materials, you should always consider alternatives with a better carbon footprint, such as sheep’s wool for insulation, clay or of course wood.

There are also innovative, ecological alternatives to conventional building materials, such as “green steel” or “green concrete”, the production of which uses hydrogen instead of coal, helping to drastically reduce CO2 emissions. EPDs (environmental product declarations) are a helpful guide in this context. They contain precise information on the measurable environmental impact of individual products, taking into account the manufacturing process. This makes it easy to compare the life cycle assessment of different types of cement, among other things.

And fourth? The ultima ratio remains compensation. At Ramboll, we’re increasingly critical of this solution, which also contradicts the science-based goals for minimising emissions in the long run.

Why Is It Important to Reduce Embodied Carbon?

We must all do everything in our power to cut CO2 in order to achieve the climate targets and keep global warming below 1.5 degrees celsius. The result of the Intergovernmental Panel on Climate Change's climate report published in August 2021 is as clear as it is frightening: the 1.5 degree mark is only possible through enormous efforts; the carbon budget, i.e. the amount of CO2 that our atmosphere can still absorb, is almost exhausted. We must act now. All of us must act and immediately. After all, sustainable transformation is only feasible if everyone is on board.

The construction industry has an extremely large lever, which means it’s realistic to expect that a great deal of CO2 can be saved here. According to the experts at the World Green Building Council, it’s possible to reduce CO2 emissions from buildings and infrastructure by a whopping 40 percent by 2030 and even achieve climate neutrality by 2050.

We should definitely seize this opportunity!

Sustainable Buildings

Using Timber Instead of Cement and Steel

Sustainable, Climate-Neutral and Cost-Efficient